- Home

- About Us

-

Products

-

Water Treatment Systems

-

Mineral water plant project

-

Industrial Reverse osmosis plants

-

Media Filters

-

Ultra Filtration Systems

-

Chlorination Plants

-

Iron Removal Systems

-

Fluoride Removal Systems

-

Seawater Desalination Systems

-

Softener Systems

-

Demineralization plant (DM plant)

-

Clarifiers

-

Dosing & ph Boosters Units

-

Domestic RO Systems

-

Mineral water plant project

- Industrial Waste Water Treatment

- Sewage Treatment

- Effluent Recycling

-

Water Treatment Systems

- Applications

- Gallery

- Contact Us

-

- Home

- About Us

- Products

-

- Water Treatment Systems

-

- Mineral water plant project

- Industrial Reverse osmosis plants

- Media Filters

- Ultra Filtration Systems

- Chlorination Plants

- Iron Removal Systems

- Fluoride Removal Systems

- Seawater Desalination Systems

- Softener Systems

- Demineralization plant (DM plant)

- Clarifiers

- Dosing & ph Boosters Units

- Domestic RO Systems

- Industrial Waste Water Treatment

- Sewage Treatment

- Effluent Recycling

- Applications

- Gallery

- Contact Us

Water Treatment Systems

Mineral water plant project

WHY SHOULD WE GO FOR MINERAL WATER BUSINESS?

As you know that now a days, lots of diseases are occurring because of impure water, if people don’t drink pure water they can’t keep balance of their health. Pure water is very important for everyone i.e. from younger one to elder one. For that we can consider our proverb “Prevention is better than cure.” When we are talking about pure water, we are happy to announce that we “SLWATER SOLUTIONS ” always stands at higher level in quality.

In today’s time, you know that salt level and T.D.S in water increases day by day which affects the health of person. So, awareness to drink pure water increases day by day in public. People incur lots of rupees to avail the mineral water. So for that much big popularities are jumping into this business to avail the facility of pure water even to normal person and they are earning more profit by this. It is proven very prominent business globally and very fast moving and profit making business.

PRIME REASONS MAKES IT PREMIUM BUSINESS

- LONG-STANDING BUSINESS: Never ending demand Essentiality has made it long-term business.

- HIGHEST PROFITABILITY : Best in consumable industries.

- INVESTMENT: From 1 lac – 1 cr. any type of business class/investor can afford.

- GRAND FOR BUSINESS: Government facilities like subsidy 35% to 50% / Bank loan up to 85%

- LOW PAYBACK PERIOD : You may get your money back in 12-24 months.

- STATUS BUSINESS : Give you immense response with many,

MANUFACTURING STAGE WISE INSPECTION

After fabrication of the unit At the time of assembling of the unit. While fitting of sealed pack Membrane Inspection of fully assembled plant.

ZERO MAINTENANCE

With the best design our plant has absolute zero maintenance. The replacement of consumable is also low. Further, preventive and periodic maintenance are easy and can be done by any persons.

WE DO ISI AND NON-ISI PACKAGED DRINKING WATER PLANT ON TURNKEY BASIS

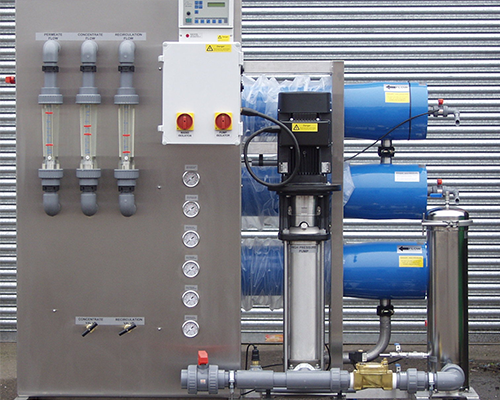

Industrial Reverse osmosis plants

Reverse Osmosis (RO) is a process of physical separation of dissolved solids and minerals present in water. This technology uses the principle of osmosis, wherein the mineral concentration of raw water is reduced by applying high pressure through a semi-permeable membrane.

Reverse Osmosis (RO) is a widely accepted unit operation for industrial water purification. The water is typically pressured between 150 to 600 psig and pass through either thin film composite or cellulose acetate membranes. Typical RO recoveries are between 70-90%.

The most important factor in treating industrial wastewater with Reverse Osmosis (RO) is the pretreatment that protects the membrane against organic fouling, mineral scaling and chemical degradation. Before reverse osmosis should be considered, a complete action/anion balance is required and potential foulants must be identified. High BOD and COD levels can also contribute to membrane fouling. A wide range of pretreatment technologies is available.

The effluent discharged to the sewer typically contains between 200 to 10,000 parts per million (ppm) total dissolved solids (TDS). With the proper pretreatment technology followed by RO, this water can be recycled

We consider your inlet water quality and capacity requirements and offers you optimised combination. This choice is dependent on different flux rates, pump models, membrane types and inlet water quality. It gives the right solutions, reduced

PRIME REASONS MAKES IT PREMIUM BUSINESS

- LONG-STANDING BUSINESS: Never ending demand Essentiality has made it long-term business.

- HIGHEST PROFITABILITY : Best in consumable industries.

- INVESTMENT: From 1 lac – 1 cr. any type of business class/investor can afford.

- GRAND FOR BUSINESS: Government facilities like subsidy 35% to 50% / Bank loan up to 85%

- LOW PAYBACK PERIOD : You may get your money back in 12-24 months.

- STATUS BUSINESS : Give you immense response with many,

MANUFACTURING STAGE WISE INSPECTION

After fabrication of the unit At the time of assembling of the unit. While fitting of sealed pack Membrane Inspection of fully assembled plant.

ZERO MAINTENANCE

With the best design our plant has absolute zero maintenance. The replacement of consumable is also low. Further, preventive and periodic maintenance are easy and can be done by any persons.

WE DO ISI AND NON-ISI PACKAGED DRINKING WATER PLANT ON TURNKEY BASIS

Media Filters

Multi-media filters represent a significant improvement over single-media filters. This is due primarily to improved filter bed action based on the innovative use and selection of filter media. Multi-media filtration permits delivery of high quality filtered water at much faster flow rates, as compared to a conventional sand filter.

In a conventional sand filter, lighter and finer sand particles are found at the top of the filter bed, and coarser, heavier sand particles remain at the bottom after backwashing. Filtration takes place in the top few inches of the filter bed.

The multi-media filter is radically different. The multi-media filter bed, in comparison to the sand filter bed, is upside down. Coarse, but lighter, particles backwash to the top, whereas finer, but heavier, particles remain at the bottom of the bed. The innovation lies in the selection of suitable media. This configuration has many advantages. The entire bed acts as a filter, rather than only the top few inches. Turbidity is trapped throughout the bed, enabling the filter to hold far more solids filtered from the water before backwashing is necessary.

PRIME REASONS MAKES IT PREMIUM BUSINESS

- LONG-STANDING BUSINESS: Never ending demand Essentiality has made it long-term business.

- HIGHEST PROFITABILITY : Best in consumable industries.

- INVESTMENT: From 1 lac – 1 cr. any type of business class/investor can afford.

- GRAND FOR BUSINESS: Government facilities like subsidy 35% to 50% / Bank loan up to 85%

- LOW PAYBACK PERIOD : You may get your money back in 12-24 months.

- STATUS BUSINESS : Give you immense response with many,

MANUFACTURING STAGE WISE INSPECTION

After fabrication of the unit At the time of assembling of the unit. While fitting of sealed pack Membrane Inspection of fully assembled plant.

ZERO MAINTENANCE

With the best design our plant has absolute zero maintenance. The replacement of consumable is also low. Further, preventive and periodic maintenance are easy and can be done by any persons.

WE DO ISI AND NON-ISI PACKAGED DRINKING WATER PLANT ON TURNKEY BASIS

Mineral water plant project

WHY SHOULD WE GO FOR MINERAL WATER BUSINESS?

As you know that now a days, lots of diseases are occurring because of impure water, if people don’t drink pure water they can’t keep balance of their health. Pure water is very important for everyone i.e. from younger one to elder one. For that we can consider our proverb “Prevention is better than cure.” When we are talking about pure water, we are happy to announce that we “SLWATER SOLUTIONS ” always stands at higher level in quality.

In today’s time, you know that salt level and T.D.S in water increases day by day which affects the health of person. So, awareness to drink pure water increases day by day in public. People incur lots of rupees to avail the mineral water. So for that much big popularities are jumping into this business to avail the facility of pure water even to normal person and they are earning more profit by this. It is proven very prominent business globally and very fast moving and profit making business.

PRIME REASONS MAKES IT PREMIUM BUSINESS

- LONG-STANDING BUSINESS: Never ending demand Essentiality has made it long-term business.

- HIGHEST FPROFITIBILITY: Best in consumable industries.

- INVESTMENT: From 1 lac – 1 cr. any type of business class/investor can afford.

- GRAND FOR BUSINESS: Government facilities like subsidy 35% to 50% / Bank loan up to 85%

- LOW PAYBACK PERIOD : You may get your money back in 12-24 months.

- STATUS BUSINESS: Give you immense response with many,

MANUFACTURING STAGE WISE INSPECTION

After fabrication of the unit At the time of assembling of the unit. While fitting of sealed pack Membrane Inspection of a fully assembled plant.

ZERO MAINTENANCE

With the best design, our plant has absolute zero maintenance. The replacement of consumable is also low. Further, preventive and periodic maintenance is easy and can be done by any persons.

WE DO ISI AND NON-ISI PACKAGED DRINKING WATER PLANT ON TURNKEY BASIS

Chlorination plants

Water chlorination is the process of adding chlorine or hypochlorite to water as a method of water purification to make it fit for human consumption as drinking water. In particular, chlorination is used to prevent the spread of waterborne diseases.

We bring forth highly efficient Chlorination Plant such as water chlorination plant, gaseous chlorination plant and many more. The Water Chlorination Plant that we offer is used for the purification of water. Our Chlorination Plants are made from optimum quality raw materials like PVC and Teflon that enhance their resistance and strength. Our all plants are of durable nature and require low maintenance cost. These plants are very easy to install and operate.

Details of Components

They are mounted on a big panel board ( 4’ X 2’ ),they consist of Chlorine flow meter, primary filter and safety gauge on its top. Safety loop with nuts at both ends. Besides, there are plastic parts such as secondary filter with NRV on top. Chlorine water mixing chamber and chlorine water solutions. In addition, there will be gas bend and water bend joining three PVC chambers and Teflon pipe connecting chlorine cylinder to the Chlorine flow meter.

Liquefied chlorine drawn from a steel cylinder gets vaporized at normal room temperature and is led through Teflon connecting tube to the primary filter on the panel board which would arrest all possible cylinder impurities in gas so that they would not abstract the flow of gas through small apertures in the plant. Safety gauge on the primary filter will show pressure only in case of any blockage in any part of the plant. Flow meter will show the flow of chlorine in gms/hour. There will be PVC ‘U’ bend to convey gas from Primary filter to the secondary filter where the gas will be further screened to eliminate all impurities. There will be NRV on top of the secondary filter, hence only chlorine will pass onwards and prevent water to flow back in filter. Water introduced at bottom of the mixing chamber and gas come from top get mixed thoroughly and will flow by a water bend at top into the adjoining solutions. The solution will be again mixed thoroughly in the solutions and will be further passed gravity to the sump through the PVC outlet and pipe. Usually, one liter of water is required for every five grams of gas for making solution in mixing chamber.

Iron Removal Systems

To Remove Iron From Water you need to install an Iron Water Filter which will help remove iron from your water, iron in your water leads to red staining in appliances and clothing and in toilet bowls.Depending on how much iron is in your water will determine what kind of an iron filter you need, both of our systems are very cost effective.

It's important to understand that if you have iron in your water and your replacing your water softener with a new Scale Reduction System or any of our Calcium Reduction Systems, you will need to address the iron otherwise you will have to stain, you will see it in toilet bowls first and it could damage your new system.Your old water softener was able to remove iron from water up to .5 ppm of iron, this is why you may not have noticed it when you had the softener.

One of the most common contaminants of a well and even municipal water systems is iron. Iron contamination can be found in two general forms, ferric iron which consists of particles of solid iron (rust) that can be removed by mechanical water filters (sediment filters), and ferrous or dissolved iron which must be removed from water by special iron water filters.In addition to causing an unpleasant metallic taste, iron in drinking and household water can cause unsightly staining of plumbing fixtures and laundry.

Unfortunately, most whole house water filter systems designed for the removal of iron from water are relatively expensive and require significant user-monitoring and maintenance. purchase and operate on an ongoing basis. After an exhaustive search, we found a specialty iron reduction filter cartridge designed to remove light to moderate ferrous iron levels from water. If your iron content is no more than 3ppm, you can easily remove it with our Iron Reduction filter cartridge installed BEFORE your Scale Reduction Equipment. Our Iron Water Filter cartridge system effectively removes iron, manganese, and hydrogen sulfide! (rotten egg smell) from municipal or well water.Iron content over 5 ppm iron (or about 2 ppm hydrogen sulfide) requires a better filtration system. This is where our Iron Filter should be used.

Fluoride Removal Systems

Fluoride - Health Concerns?

For over fifty years water fluoridation has been an accepted part of the public health program in many western countries. However, there is a significant and growing body of evidence indicating that the original studies used to support the introduction of fluoridation may have been deeply flawed at best and corrupted and compromised science at worst.

“Over the past ten years, a large body of peer-reviewed science has raised concerns that fluoride may present unreasonable health risks, particularly among children, at levels routinely added to tap water in American cities.” - US ENVIRONMENTAL WORKING GROUP - July 2005

Questions about fluoride effectiveness for cavity prevention is also being compounded by the fact that fifty years of real-world research has discovered enough evidence to at least question the effect of long-term exposure to fluoride, particularly for infants and children. Some research suggests it may have deleterious effects on;

- Thyroid regulation

- Bone development

- Brain function and IQ

- Kidney function

- Gene expression

- Cell regulation

Due to these concerns, about what is essentially a compulsory form of public medication, many alternative healthcare professionals, researchers and consumers are demanding fluoride-free drinking water.

“The urgent consideration is total fluoride ingestion -- how much fluoride are people taking into their bodies from fluoride air pollution, from the soil, from water, from products processed in fluoridated water, from pharmaceuticals, pesticides, herbicides and so forth?." - Ralph Nader - Consumer Advocate.

Fluoride In Nature

Fluorine is a natural trace element and exists in almost all soils. In elemental form fluorine is a flammable, irritating, and toxic halogen gas that is one of the most powerful oxidizing agents known. It therefore occurs naturally only in the reduced (fluoride, Fl-) form in combination with other minerals. Fluoride is classified as any binary compound of fluorine with another element. Fluoride compounds make up approximately 0.08 percent of the earth's crust. Fluorspar, cryolite, and fluorapatite are the most common fluoride producing compounds known. Fluorspar contains the highest percentage of fluoride by weight, as calcium fluoride (CaF2), of the minerals mentioned

Fluoride In Drinking Water

Perhaps the most widely known use of fluoride is its addition to public drinking water supplies at about one milligram per liter (mg/L) of a fluoride salt, measured as fluoride, for the purpose of reducing tooth decay. This is achieved at the municipal treatment plant by injecting or feeding a solution of hydrofluosilicic acid, sodium silicofluoride, or sodium fluoride into the treated water stream. It is the fluoride ion in mineral ionic form that occurs in water, bones, teeth, and public drinking water supplies. About 144 million people it was estimated in 1992 drink fluoridated water at levels ranging from 0.7 to 1.2 mg/L.

SL Fluoride Water Filter

The SL Fluoride Series uses bone charcoal or bone char is reported to be an effective means for the reduction of fluoride. Bone charcoal contains a carbon structure while supporting a porous hydroxyapatite matrix (a calcium phosphate hydroxide in crystalline form which is rich in surface ions which can be readily replaced by fluoride ion). Adsorption and ion exchange are thought to be the mechanism for fluoride reduction by bone char.

Effects of Fluoride

Some water systems with naturally occurring fluoride must treat their water supply to remove the excess fluoride to comply with the Safe Drinking Water Act limits. Children under nine years of age exposed to levels of fluoride greater than about two mg/L may develop a condition known as mottling or discoloration of the permanent teeth. In certain cases the teeth become chalky white in appearance. The U.S. Environmental Protection Agency has advised a secondary maximum contaminant level (SMCL) limit of two mg/L to protect against this aesthetic or cosmetic adversity from fluorides in drinking water. Further, federal regulations require that fluoride not exceed a concentration of four mg/L in drinking water. This is an enforceable maximum contaminant level (MCL) standard; it has been established to protect public health.

Exposure to drinking water levels above four mg/L for many years may result in cases of crippling skeletal fluorosis, which is a serious bone disorder resembling osteopetrosis and characterized by extreme density and hardness and abnormal fragility of the bones (sometimes called .marble bones..) When a community water system exceeds the MCL of four mg/L, it must notify each of its customers by issuing a public notice to those customers. This notice outlines the limitations and health effects from high fluoride levels in drinking water and points out home treatment systems and bottled water as possible drinking water source alternatives.

Seawater Desalination Systems

Desalination, desalinization, and desalinization refer to any of several processes that remove some amount of salt and other minerals from saline water. More generally, desalination may also refer to the removal of salts and minerals, as in soil desalination.

Salt water is desalinated to produce fresh water suitable for human consumption or irrigation. One potential byproduct of desalination is salt. Desalination is used on many seagoing ships and submarines. Most of the modern interest in desalination is focused on developing cost-effective ways of providing fresh water for human use. Along with recycled wastewater, this is one of the few rainfall-independent water sources.Salt water is desalinated to produce fresh water suitable for human consumption or irrigation. One potential byproduct of desalination is salt. Desalination is used on many seagoing ships and submarines. Most of the modern interest in desalination is focused on developing cost-effective ways of providing fresh water for human use. Along with recycled wastewater, this is one of the few rainfall-independent water sources.

Sl water solutions are committed to being the leader in membrane technology with a focus on breaking barriers related to pretreatment, energy recovery, and overall water recovery. We are progressively making strides in optimizing the lifecycle cost and increasing the reliability of Seawater Reverse Osmosis (SWRO) installations for reverse osmosis desalination. Our approach is to take complete responsibility for SWRO installations to ensure complete design integration From intake to outfall, sl water solutions can take single point responsibility.

- Capability to design and execute integrated desalination projects on an EPC basis.

- Potabilization system design for Boron removal as per global standards.

- n-house reverse osmosis desalination programming capabilities that lower overall start-up costs, improve reliability and ensure better plant availability.

Softener Systems

WHY SHOULD WE GO FOR MINERAL WATER BUSINESS?

As you know that nowadays, lots of diseases are occurring because of impure water, if people don’t drink pure water they can’t keep a balance of their health. Pure water is very important for everyone i.e. from younger one to elder one. For that, we can consider our proverb “Prevention is better than cure.” When we are talking about pure water, we are happy to announce that we “SLWATER SOLUTIONS ” always stands at a higher level of quality.

In today’s time, you know that salt level and T.D.S in water increases day by day which affects the health of a person. So, awareness to drinking pure water increases day by day in public. People incur lots of rupees to avail the mineral water. So for that much big popularities are jumping into this business to avail the facility of pure water even to a normal person and they are earning more profit by this. It is proven very prominent business globally and very fast moving and profit making business.

PRIME REASONS MAKES IT PREMIUM BUSINESS

- LONG-STANDING BUSINESS: Never ending demand Essentiality has made its long-term business.

- HIGHEST PROFITABILITY: Best in consumable industries.

- INVESTMENT: From 1 lac – 1 cr. any type of business class/investor can afford.

- GRAND FOR BUSINESS: Government facilities like subsidy 35% to 50% / Bank loan up to 85%

- LOW PAYBACK PERIOD: You may get your money back in 12-24 months.

- STATUS BUSINESS: Give you immense response with many,

MANUFACTURING STAGE WISE INSPECTION

After fabrication of the unit At the time of assembling of the unit. While fitting of sealed pack Membrane Inspection of a fully assembled plant.

ZERO MAINTENANCE

With the best design, our plant has absolute zero maintenance. The replacement of consumable is also low. Further, preventive and periodic maintenance is easy and can be done by any persons.

WE DO ISI AND NON-ISI PACKAGED DRINKING WATER PLANT ON TURNKEY BASIS

Demineralization plant (DM plant)

Demineralization is the process of removing mineral salts from water by using the ion exchange process.Demineralized water is also known as Deionized water, water that has had its mineral ions removed. Mineral ions such as cations of sodium, calcium, iron, copper, etc and anions such as chloride, sulfate, nitrate, etc are common ions present in water. Deionization is a physical process which uses specially-manufactured ion exchange resins which provides ion exchange site for the replacement of the mineral salts in water with water forming H+ and OH- ions. Because the majority of water impurities are dissolved salts, deionization produces a high purity water that is generally similar to distilled water, and this process is quick and without scale buildup. De-mineralization technology is the proven process for treatment of water. A DM Water System produces mineral free water by operating on the principles of ion exchange, Degasification, and polishing. Demineralized Water System finds wide application in the field of steam, power, process, and cooling.

Principle

Raw water is passed via two small polystyrene bead-filled (ion exchange resins) beds. While the cations get exchanged with hydrogen ions in the first bed, the anions are exchanged with hydroxyl ions, in the second one.

Process

In the context of water purification, ion-exchange is a rapid and reversible process in which impurity ions present in the water are replaced by ions released by an ion-exchange resin. The impurity ions are taken up by the resin, which must be periodically regenerated to restore it to the original ionic form. (An ion is an atom or group of atoms with an electric charge. Positively-charged ions are called cations and are usually metals; negatively-charged ions are called anions and are usually non-metals).

Advantages

- Variety of cost-effective standard models.

- Improved aesthetics and rugged design.

- User-friendly, low maintenance and easy to install.

- Simpler distribution and collection systems

- Quick availability.

- Pre-dispatch assembly check.

- The multiport valves are top mounted as well as side mounted with the necessary high-pressure rating PVC piping.

- Single valve operation as compared to the six valves in conventional filters

- Each operating step is clearly marked on the valve, thereby eliminating chances of error in the operating sequence.

- A single valve assembly, with its simplified frontal Piping, simpler distribution collecting systems is Very easy to install.

- Rust free

- Less power consumption

- Durable

- Economical

- High shelf life

Major Applications

- Boilers feed water, Textiles, Pharmaceuticals, Chemicals, Breweries, Swimming pools, Potable Water, Hospitals, Automobile, and Battery, Fertilizers.

- Ion Exchange Plants

We Offer

Our company offers excellent quality Demineralization Plant manufactured through a technically advanced process. Demineralization Water Treatment Plant, provided by our company, is highly demanded in various industries and municipal sectors. Today, we are regarded as one of the trusted Demineralization Water Plant Exporters.

Portable or Mini- DM Water Treatment Plant

The water free from any mineral is called De- Mineralised Water (D.M.Water). Naturally, occurring water has various salts in a dilute form which are called dissolved solids (TDS). When the water having such mineral is required to be free from this, it is to be treated in Ion Exchange Resins column (H form) which adsorbs the positively charged ion. Now the cations free passed through Anion Resin Column (OH form) which adsorbs the negatively charged anions and water free from the total ions shall come out from the system.

Mini DM Plant Specifications

- Model: eDM-5

- Flow rate: 50 to 80 Lit/hr.

- Space requirement: very compact- 1 m x 1m

- Power: NIL, Min inlet pressure 0.5 kg/cm2

- Output TDS: Less than 10 ppm

- Output DM Qty.: 500 Lit at 100 ppm TDS

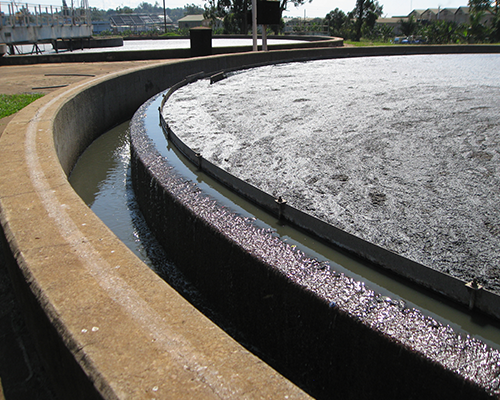

Clarifiers

Clarifiers are settling tanks built with mechanical means for continuous removal of solids being deposited by sedimentation.[1] A clarifier is generally used to remove solid particulates or suspended solids from the liquid for clarification and (or) thickening. Concentrated impurities, discharged from the bottom of the tank are known as sludge, while the particles that float to the surface of the liquid are called scum.

Principle

Clarification is the oldest and most widely used operation in the effective treatment of wastewater. The operation consists of removing sediment, turbidity and floating material from raw wastewater. The two types of wastewater clarifiers provided by Sl Water solutions(SLWS) are a parallel plate and the circular mechanical type described below. There are also two types of circular mechanical clarifiers offered by PCS: circular center feed, and circular peripheral flow types. The SLWS circular mechanical clarifiers include circular center feed and circular peripheral flow types.

Circular Center Feed Wastewater Clarifiers

The SLWS circular center feed clarifier operates with the effluent entering through a center stilling well with the flow being forced downward. This ensures the proper residence time of the water in the clarifier to allow for the settling of the solids. The water then rises and exits through a wall mounted weir trough that is placed on the inner circumference of the clarifier. A skimmer sweeps over the surface of the clarifier to collect any floatable solids and removes them via the scum trough. A scraper arm assembly passes over the bottom of the clarifier to densify and condition the settled solids prior to being drawn off for additional processing.

Circular Peripheral Flow Wastewater Clarifiers

The circular peripheral flow clarifier offered by PCS operates with the water flow entering the system at the periphery. The water flow is evenly distributed and spirals down around the annulus of the clarifier by means of a specially designed baffle skirt. This configuration provides for a maximum settling of solids toward the sludge pick-up. The water flow exits the clarifier through a center supported weir trough. A scraper arm assembly sweeps the bottom of the clarifier to densify and condition the settled solids prior to being drawn off for additional processing.

Circular Clarifier

Circular center feed and circular peripheral flow clarifiers offer the user a variety of features and applications. PCS circular clarifiers are found in municipal, commercial, and industrial applications; they can be used for primary and secondary clarification, and they are available in steel or the internal components can be packaged for installation in a concrete construction (concrete by others).

Circular Center Feed

Flow enters through the center stilling well and is forced downward, ensuring a proper settling time before it rises and exits through the wall-mounted weir troughs. The skimmer covers the surface of the clarifier between the center stilling well and the scum baffle.

Circular Peripheral Flow

Flow enters at the periphery, where it is evenly distributed and spiraled downward around the annulus by means of the specially designed baffle skirt, providing for maximum settling toward the sludge pickup. Flow exits through the center-supported weir troughs.

Dosing & ph boosters units

The dosing/chlorinating unit is meant to dose a chemical into the water. The chemicals can be chlorine for freshwater systems, corrosion inhibitors for main engine cooling water, pH adjustment of fresh water etc.The unit consists of a dosing pump, a control cabinet, an injection valve and a container for the chemical. The container is equipped with a low-level alarm which stops the pump in case chemical runs out, a suction valve and a manual agitator. All components are mounted on a stable steel frame for easy installation.

The most common application is that the dosing unit is being used to pre-chlorinate or pH-adjust fresh water, pre-chlorinate evaporated water or bunker water, on its way to fresh water holding tank, and to rechlorinate water before it is distributed. The prechlorination systems are normally controlled by flow meters in bunker water flow line and evaporated water flow line respectively. This ensures enough chlorine dosed into the actual water flow in the water line proportionately.

Main Features

- Corrosion Inhibits Chemical for Main Engine Cooling Water

- pH-adjust Water

- Chlorinate Fresh Water

- Easy Installation and Operation

- Sl water solutions(SLWS) offer an extensive range of high-performance chemical dosing pumps and chemical metering equipment suitable for most industrial and commercial applications.

- SLWS full range of metering pumps includes electronic dosing pumps, mechanical diaphragm dosing pumps and peristaltic pumps.

- All SLWS are engineered to the highest quality standards and offer excellent long-term reliability, accuracy and control.

- SLWS chemical metering pumps are ideal for applications including water treatment chemical dosing, cooling tower biocide dosing, inhibitor dosing, pH control and adjustment, detergent dosing, swimming pool chemical treatment applications and many other commercial and industrial process applications.

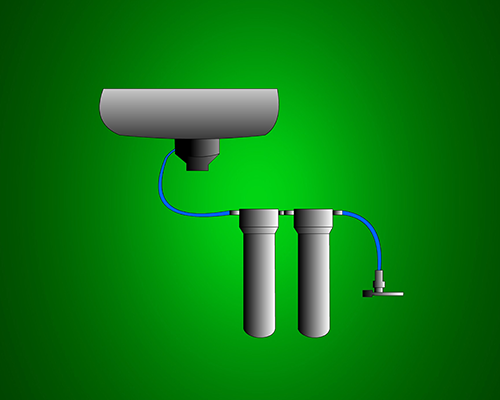

Domestic RO systems

We manufacture and export Domestic RO Systems. It is a multi-staged and advanced domestic water treatment system. This system is known to bring even groundwater and hard water to bottle water standards, using RO technology, which is being used worldwide to make bottled mineral water. Our RO systems are designed for durability and protection. They completely purify the water with ease making it safe to drink.

Features

- A high purifying capacity of Saffire Spring Membrane which produces 12 liters per hour

- Purifies impure water to sweet pure drinking water

- Fully automatic with auto start & auto off

- Removes active and inactive bacteria and viruses

- Water available on demand, even in absence of electricity

- Low cost of maintenance and consumables

About Us

We are glad to introduce ourselves as “SL Water Technologies” vijayanagaram is led by a team of experts, today being one of the leading manufacturers of water & wastewater treatment in India.