- Home

- About Us

-

Products

-

Water Treatment Systems

-

Mineral water plant project

-

Industrial Reverse osmosis plants

-

Media Filters

-

Ultra Filtration Systems

-

Chlorination Plants

-

Iron Removal Systems

-

Fluoride Removal Systems

-

Seawater Desalination Systems

-

Softener Systems

-

Demineralization plant (DM plant)

-

Clarifiers

-

Dosing & ph Boosters Units

-

Domestic RO Systems

-

Mineral water plant project

- Industrial Waste Water Treatment

- Sewage Treatment

- Effluent Recycling

-

Water Treatment Systems

- Applications

- Gallery

- Contact Us

-

- Home

- About Us

- Products

-

- Water Treatment Systems

-

- Mineral water plant project

- Industrial Reverse osmosis plants

- Media Filters

- Ultra Filtration Systems

- Chlorination Plants

- Iron Removal Systems

- Fluoride Removal Systems

- Seawater Desalination Systems

- Softener Systems

- Demineralization plant (DM plant)

- Clarifiers

- Dosing & ph Boosters Units

- Domestic RO Systems

- Industrial Waste Water Treatment

- Sewage Treatment

- Effluent Recycling

- Applications

- Gallery

- Contact Us

Effluent Recycling

Recycling of Industrial Waste Water & Sewage Water

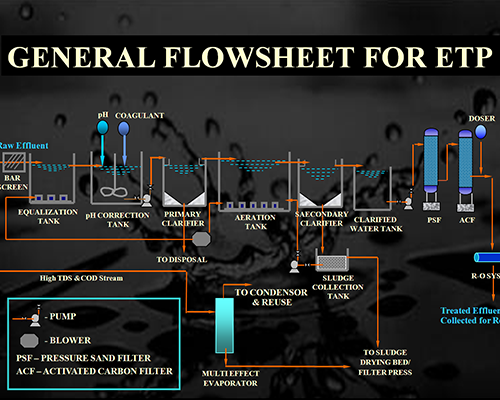

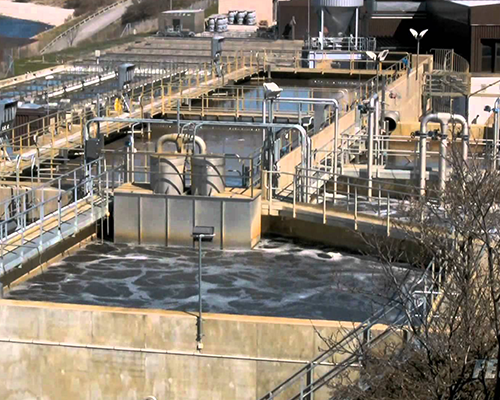

Industrial wastewater treatment covers the mechanisms and processes used to treat wastewater that is produced as a by-product of industrial or commercial activities. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a sanitary sewer or to a surface water in the environment. Most industries produce some wastewater although recent trends in the developed world have been to minimize such production or recycle such wastewater within the production process. However, many industries remain dependent on processes that produce wastewaters.

Coagulation may be used for the clarification of industrial wastes containing colloidal and suspended solids. Paperboard wastes can be coagulated effectively with low dosages of alum. Silica or polyelectrolyte aids in the formation of a rapid-settling flock

One of the major applications of ion exchange in industrial waste treatment has been in the plating industry, where chromium recovery and water reuse have resulted in considerable savings.

Key Features

- Provides practical solutions for the treatment and recycling of industrial wastewater via case studies

- Instructive articles from expert authors give a concise overview of different physicochemical and biological methods of treatment, cost-to-benefit analysis, and process comparison.

- Supplies you with the relevant information to make quick process decisions.

Membrane Process

Membranes are commonly used at various stages in the water treatment process, but what exactly is a membrane process? It’s any method that relies on a membrane to filter or remove particles from water.

Membranes are commonly used at various stages in the water treatment process, but what exactly is a membrane process? It’s any method that relies on a membrane to filter or remove particles from water.

Reverse osmosis

Reverse osmosis reverses the process. Pressure is used to force a pure solvent through a semi-permeable membrane. Water typically passes easily through membranes because its molecules are small. The pore size of a reverse osmosis filter is general 0.0001 of a micron. Reverse osmosis is most often used for desalination of seawater and brackish water for potable and industrial applications, but also for wastewater treatment and water reuse. It can also be used to remove trace phosphates, calcium, heavy metals, and other substances.

Ultrafiltration

Another membrane process is ultrafiltration. These membranes have a filter size of between roughly 0.1 and 0.01 microns. This allows for the retention of proteins, fatty acids, macromolecules, bacteria, and suspended solids in a liquid. In water treatment, the ultrafiltration process is able to remove bacteria, protozoa, and some viruses from the water.

Combined Treatments

Often these processes can be used in combination to provide a comprehensive water treatment solution. One example is the Central Puerto facility in Buenos Aires, Argentina, which needed to treat river water before it was used in its industrial equipment. Ultrafiltration was used in combination with reverse osmosis to create demineralized water for the plant’s high-pressure boiler. The ultrafiltration process helped resolve issues the operation previously experienced with membrane fouling. Mine water treatment is another example application for these combined processes. The wastewater from mining operations is extremely high in total suspended solids and colloids. Ultrafiltration can remove these particles to prepare it for treatment with reverse osmosis. In some cases, the water is passed through reverse osmosis twice to reach the needed final specifications for full water treatment.

Lime soda softening

Lime soda process is the method of softening hard water. This process is now obsolete but was very useful for the treatment of large volumes of hard water.

However, it is important to note that it is not possible to remove all of the hardness from water. In actual practice, about 50 to 80 mg/L will remain as a residual hardness.

PRIME REASONS MAKES IT PREMIUM BUSINESS

- LONG-STANDING BUSINESS: Never ending demand Essentiality has made its long-term business.

- HIGHEST PROFITABILITY: Best in consumable industries.

- INVESTMENT: From 1 lac – 1 cr. any type of business class/investor can afford.

- GRAND FOR BUSINESS: Government facilities like subsidy 35% to 50% / Bank loan up to 85%

- LOW PAYBACK PERIOD: You may get your money back in 12-24 months.

- STATUS BUSINESS: Give you immense response with many,

MANUFACTURING STAGE WISE INSPECTION

After fabrication of the unit At the time of assembling of the unit. While fitting of sealed pack Membrane Inspection of a fully assembled plant.

ZERO MAINTENANCE

With the best design, our plant has absolute zero maintenance. The replacement of consumable is also low. Further, preventive and periodic maintenance is easy and can be done by any persons.

WE DO ISI AND NON-ISI PACKAGED DRINKING WATER PLANT ON TURNKEY BASIS

Zero Liquid Discharge

Zero-liquid discharge (ZLD) is a water treatment process in which all wastewater is purified and recycled; therefore, leaving zero discharge at the end of the treatment cycle. ZLD is an advanced wastewater treatment method that includes ultrafiltration, reverse osmosis, evaporation/crystallization, and fractional electrodeionization.

ZLD AT A GLANCE

- Innovators in Hybrid ZLD, merging membranes, and thermal evaporators.

- Reliable and cost-effective solutions.

- Specialized ZLD operation and maintenance services.

About Us

We are glad to introduce ourselves as “SL Water Technologies” vijayanagaram is led by a team of experts, today being one of the leading manufacturers of water & wastewater treatment in India.