- Home

- About Us

-

Products

-

Water Treatment Systems

-

Mineral water plant project

-

Industrial Reverse osmosis plants

-

Media Filters

-

Ultra Filtration Systems

-

Chlorination Plants

-

Iron Removal Systems

-

Fluoride Removal Systems

-

Seawater Desalination Systems

-

Softener Systems

-

Demineralization plant (DM plant)

-

Clarifiers

-

Dosing & ph Boosters Units

-

Domestic RO Systems

-

Mineral water plant project

- Industrial Waste Water Treatment

- Sewage Treatment

- Effluent Recycling

-

Water Treatment Systems

- Applications

- Gallery

- Contact Us

-

- Home

- About Us

- Products

-

- Water Treatment Systems

-

- Mineral water plant project

- Industrial Reverse osmosis plants

- Media Filters

- Ultra Filtration Systems

- Chlorination Plants

- Iron Removal Systems

- Fluoride Removal Systems

- Seawater Desalination Systems

- Softener Systems

- Demineralization plant (DM plant)

- Clarifiers

- Dosing & ph Boosters Units

- Domestic RO Systems

- Industrial Waste Water Treatment

- Sewage Treatment

- Effluent Recycling

- Applications

- Gallery

- Contact Us

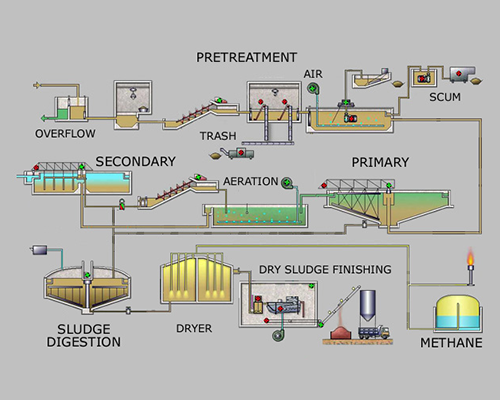

Sewage Treatment

Anaerobic and Aerobic Treatment System

What is Aerobic Wastewater Treatment?

In today’s time, you know that salt level and T.D.S in water increases day by day which affects the health of a person. So, awareness to drinking pure water increases day by day in public. People incur lots of rupees to avail the mineral water. So for that much big popularities are jumping into this business to avail the facility of pure water even to a normal person and they are earning more profit by this.

It is proven very prominent business globally and very fast moving and profit making business.

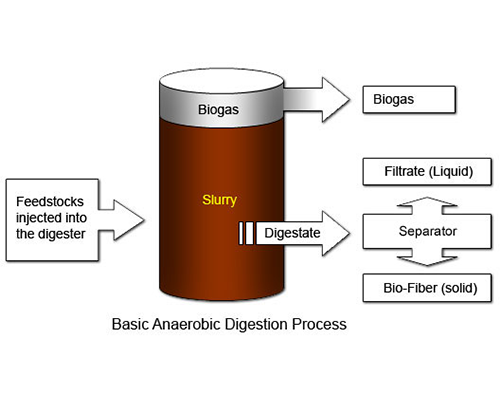

What is Anaerobic Wastewater Treatment?

Anaerobic treatment is a biological process ideally suited for the pretreatment of high-strength wastewaters that are typical of many industrial facilities. The anaerobic process utilizes naturally-occurring bacteria to break down biodegradable material in an industrial waste stream.

The anaerobic process is time-tested and does not require the purchase of special bacteria or nutrients. Because the bacteria are anaerobic they do not require oxygen like the organisms in an aerobic process. Reactors are enclosed or covered to prevent the introduction of air and the release of odors.

Applications

- Anaerobic treatment is ideal for pretreatment, pretreatment prior to aerobic treatment, and pretreatment of segregated waste streams.

- Used for standalone pretreatment, an anaerobic system can be used as the sole biological component of a treatment system for wastewater discharged to a POTW.

- Used prior to aerobic treatment, an anaerobic system can be very effective and economical for removing high concentrations of BOD and COD prior to final treatment by an anaerobic process.

- Many industrial facilities have waste streams that represent a fraction of the total flow, yet contribute a majority of the pollutant load. These high-BOD waste streams can be segregated for treatment by an anaerobic process prior to combining with the total flow. ETS anaerobic systems are very effective in wastewater treatment at a variety of industrial facilities.

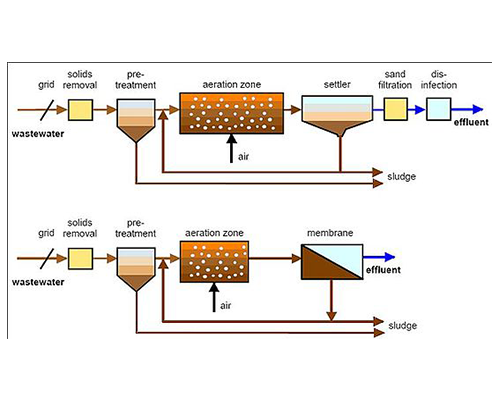

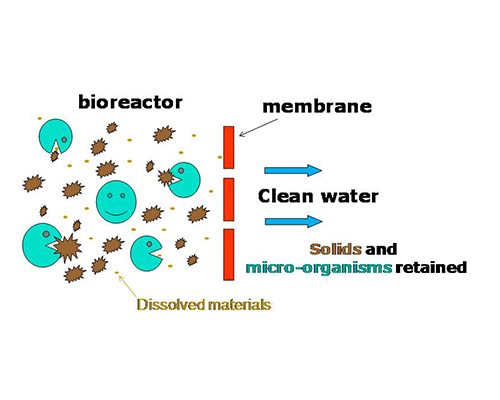

Membrane Bio-Reactors

Membrane bioreactors for wastewater treatment is a combination of a suspended growth biological treatment method, usually activated sludge, with membrane filtration equipment, typically low-pressure microfiltration (MF) or ultrafiltration (UF) membranes. The membranes are used to perform the critical solid-liquid separation function.

ADVANTAGES

- High effluent quality.

- No sludge settling problems.

- Reduced volume requirements.

The benefits of MBR includes a reduced footprint, usually 30-50% smaller than an equivalent conventional active sludge facility with secondary clarifiers and media tertiary filtration. The process also produces exceptional effluent quality capable of meeting the most stringent water quality requirements, a modular schematic that allows for ease of expansion and configuration flexibility, a robust and reliable operation and reduced downstream disinfection requirements.

Packaged Sewage Treatment Plant

Our selection of a packaged treatment plant offers the user a pre-engineered and pre-fabricated method of treating wastewater with an aerobic process. The final effluent can be released safely into the environment such as receiving streams, rivers, etc. Treated non-potable water is also being used as a new source of water to promote agricultural and aquaculture production, industrial uses, water sustainability, and reclamation uses such as irrigation, wash down, and/or artificial recharge.

The Packaged Plant Treatment System is a type of biological treatment for domestic waste using the extended aeration process. Packaged Plants are compact, self-contained, and factory prefabricated. They are able to treat 1,000 to 150,000 gallons per day, depending on your unique application.

ADVANTAGES

- Pre-engineered, pre-fabricated structures result in lower cost.

- A unit is easily transported to the customer’s project site.

- Design allows for quick turnaround time for delivery and installation.

- Treatment System is simple to operate and requires low manpower.

- User-friendly – low and easy maintenance.

- Regulatory compliant.

- Custom design/application specific systems.

- Long service life

Sewage Reclamation with Ultra Filtration

In wastewater treatment, ultrafiltration (UF) devices are used to recycle and reuse water that contains virtually no physical solids

Ultrafiltration definition, applications and industries using these process units are covered below. Ultrafiltration (UF) is a variety of membrane filtration in which forces like pressure or concentration gradients lead to a separation through a semipermeable membrane. Suspended solids and solutes of high molecular weight are retained in the so-called retentate, while water and low molecular weight solutes pass through the membrane in the permeate.

Applications Of Ultrafiltration

Ultrafiltration processes are preferred over traditional treatment methods for the following reasons

- No chemicals required (aside from cleaning).

- Constant product quality regardless of feed quality.

- Compact plant size.

When water recycling is simple, it often needs very little processing. However, when more intensive processing is required, the industry standard procedures include using UF, which is meant to remove physical solids from water by passing it through a semi-permeable membrane. Using ultrafiltration, solids are primarily captured by the filter and discarded.

Air Diffusers

An air diffuser or membrane diffuser is an aeration device typically in the shape of a disc, tube or plate, which is used to transfer air and with that oxygen into sewage or industrial wastewater. Oxygen is required by microorganisms/bacteria residents in the water to break down the pollutants. Diffusers use either rubber membranes or ceramic elements typically and produce either fine or coarse bubble.

Air diffusers are used in the biological treatment of wastewater which works on the principle of diffusion of air in liquid phase through air bubbles, broadly classified into fine and coarse bubble diffuser to meet the application suitability, engineering requirements, and economics of plant. This system is also known as Diffused Aeration Systems.

Advantages

- Low Initial Capital Costs.

- Low Operating Costs.

- Low Energy Cost/Consumption.

- Reliable Performance.

- Resistance to corrosion.

- Robust in nature

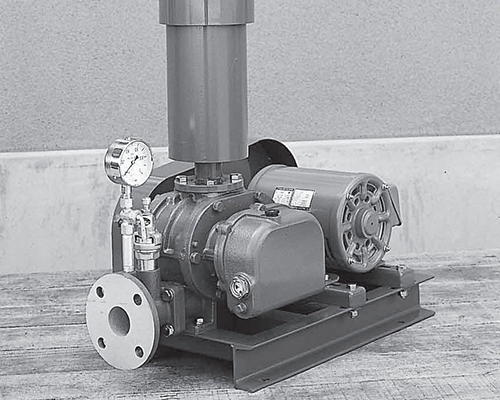

Air Blower

We offer a range of blowers that are perfectly suited for water treatment applications. Our range of energy efficient screw and turbo blowers can offer the perfect solution for any wastewater and water treatment plant.

Application of Blower in Water Treatment Plant

The impure water in water treatment plant is purified with the help of bacteria. The bacteria will purify the water by degrading the organic matter present in it. These bacteria require oxygen during the process and therefore blowers in a water treatment plant are employed in aeration tanks to provide sufficient air amount required by the bacteria to convert into oxygen required for the purification process. The rotary lobe positive displacement blowers are available today in energy-saving features and therefore can be quite economical resources for supplying air required for adding up to the oxygen content in aeration tanks in the plants. As the rotors within the blowers rotate they draw air into the blower thereby filling up space between them. The intake then closes and therefore the air will be trapped into the casing. The rotors keep on rotating until the air exits the outlet port.

About Us

We are glad to introduce ourselves as “SL Water Technologies” vijayanagaram is led by a team of experts, today being one of the leading manufacturers of water & wastewater treatment in India.